Vacuum Cutting Tool Brazing Furnace: Precision & Efficiency for High-End Tool Manufacturing

- By: Brother Furnace

- 2025-12-05 00:59

In the fiercely competitive high-end tool manufacturing sector, brazing quality is the core determinant of a tool’s performance, durability, and service life.

In this article, let's learn about Brother Furnace's vacuum cutting tool brazing furnace.

Integrating cutting-edge vacuum brazing technology and smart control systems, this professional vacuum brazing furnace redefines industry standards for tool brazing.

Tailored to diverse tool types and material properties, it delivers unparalleled precision, stability, and production efficiency, firmly establishing itself as an indispensable vacuum brazing furnace for modern tool manufacturers.

1. The Core Advantages Of The Furnace: Precision, Efficiency, and Versatility

1.1 Superior Vacuum Brazing Environment

The furnace creates a high-purity vacuum atmosphere, eliminating oxygen and moisture that cause oxidation, decarburization, and porosity in brazed joints. This ensures uniform distribution of brazing filler metal, forming dense, high-strength joints with excellent corrosion resistance.

For carbide-tipped cutting tools and diamond tools, it preserves the original properties of base materials and brazing alloys, significantly enhancing tool wear resistance and service life.

1.2 Intelligent Temperature Control & Uniform Heating

Equipped with a high-precision temperature control system and advanced heating elements, the furnace achieves a temperature uniformity of ±1 °C within the working zone.

Its intelligent programming function supports customized heating, holding, and cooling curves, adapting to brazing requirements of different tool materials—including carbide, high-speed steel, diamond, and cubic boron nitride.

Whether for small precision tools or large-scale tool batches, it ensures consistent brazing quality across all products.

1.3 High Efficiency & Energy Conservation

The furnace adopts energy-saving insulation materials and optimized thermal field design, reducing heat loss by over 25% compared to traditional brazing equipment.

Shortened heating and cooling cycles enhance production efficiency, allowing for the batch processing of up to hundreds of tools per furnace.

Additionally, its automated operation—from vacuum pumping to program execution and furnace cooling—reduces manual intervention, lowering labor costs and operational errors.

2. The Wide Application Scenarios Of The Furnace

Brother Furnace Vacuum Cutting Tool Brazing Furnace caters to a broad range of tool manufacturing needs:

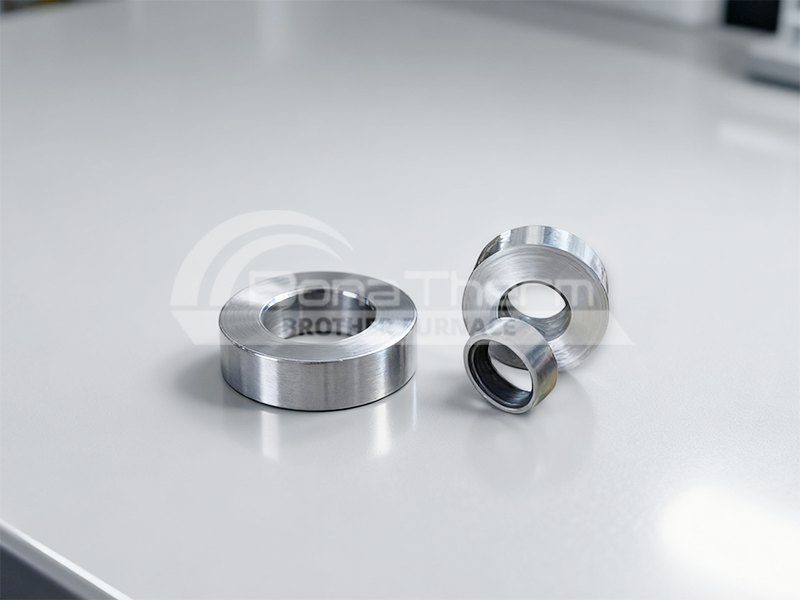

Cutting Tools: Ideal for brazing carbide-tipped end mills, drills, reamers, and inserts, ensuring sharp cutting edges and stable tool structure.

Abrasive Tools: Excels in brazing diamond saw blades, grinding wheels, and polishing tools, enhancing bonding strength between abrasive grains and substrates.

Special Tools: Suitable for brazing complex-shaped tools such as mining tools, woodworking tools, and aerospace precision tools, adapting to diverse material combinations.

3. Reliable Performance & User-Friendly Design

3.1 Robust Construction & Durability

Crafted with high-quality heat-resistant steel and corrosion-resistant materials, the furnace chamber withstands long-term high-temperature operation without deformation or performance degradation.

Strict quality control during production ensures stable operation for over 10,000 hours, minimizing maintenance downtime.

3.2 Intuitive Operation & Safety Assurance

The furnace features a user-friendly touchscreen control panel, allowing operators to set parameters, monitor processes, and store recipes easily.

Built-in multiple safety protections—including over-temperature alarm, vacuum failure protection, and pressure relief devices—ensure safe and reliable operation. Its compact design optimizes factory space utilization, while low noise and emission levels meet environmental standards.

Why Choose Brother Furnace?

Brother Furnace, a trusted name in thermal processing equipment, combines years of technical expertise with customer-centric innovation.

The Vacuum Tool Brazing Furnace undergoes rigorous testing and calibration to meet international quality standards. With professional pre-sales consultation, on-site installation, and after-sales maintenance support, Brother Furnace provides a full-cycle solution for tool manufacturers.