How to Choose the Chamber Materials for Vacuum Sintering Furnace?

- By: Brother Furnace

- 2025-12-03 01:02

As core equipment for material processing, vacuum sintering furnaces have chamber materials that directly impact sintering temperature, atmosphere stability, product purity, and process cost.

Brother Furnace offers five mainstream chamber materials—alumina ceramic fiber, molybdenum, graphite, tungsten, and heat-resistant steel—each with unique properties tailored to diverse industrial needs.

This article guides the selection process by focusing on material characteristics, applicable processes, key advantages, and necessary precautions.

1. Alumina Ceramic Fiber Chamber: Energy-Efficient for Medium Temperatures

Made from high-purity alumina-silica composites via special forming, this lightweight chamber boasts excellent heat resistance and low thermal conductivity. It is suitable for medium-temperature sintering of electronic ceramics, structural ceramics, and magnetic materials, such as MLCCs, maintaining a temperature uniformity of ±5℃ to prevent product defects.

Its thermal conductivity is 1/10 that of traditional refractory bricks, cutting energy consumption by over 30%—ideal for mass production. Precautions: Avoid prolonged operation above 1200℃ in vacuum sintering furnaces and minimize contact with fluorine -or alkali-metal-containing materials that may corrode the chamber.

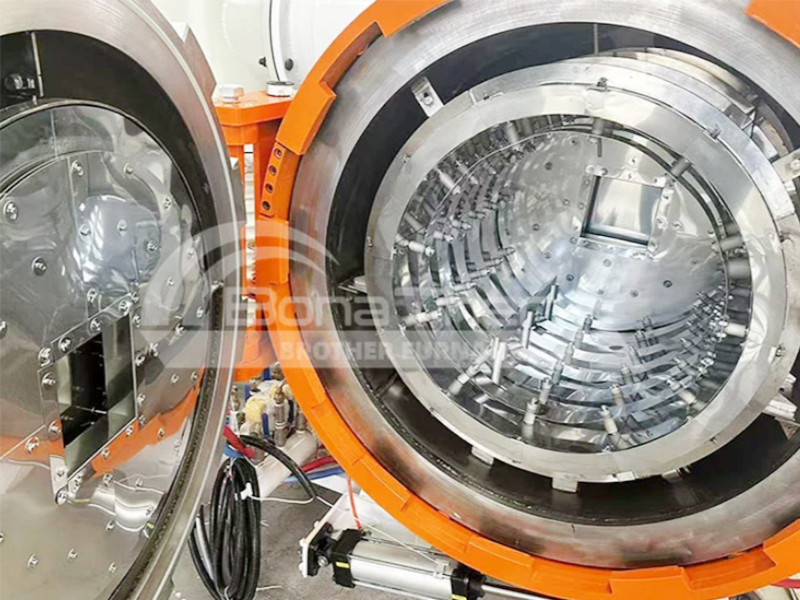

2. Molybdenum Chamber: Purity for High-Temperature Metal Sintering

Leveraging molybdenum’s 2620℃ melting point, high-temperature strength, and vacuum stability, this chamber is perfect for sintering titanium alloys, superalloys, and refractory metals. It prevents material contamination and ensures uniform heating, critical for titanium alloy blades and refractory metal powder metallurgy.

Operations require maintaining a furnace vacuum above 10⁻³ Pa to avoid molybdenum oxidation. Avoid using high-carbon materials in such vacuum molybdenum thermal furnaces, as they form brittle molybdenum carbide, which can damage the chamber.

3. Graphite Chamber: For Carbon-Based Materials & High Temperatures

Crafted from high-density isostatic pressed graphite, this chamber withstands temperatures of up to 2200℃ in the long term and excels in thermal conductivity. Its carbon content makes it exclusive for carbon-based materials, widely used in sintering carbon fiber composites, graphite electrodes, and silicon carbide ceramics.

It creates stable reducing atmospheres to prevent oxidation and aids vacuum degassing for metal powders, making it a key component in vacuum graphite furnaces. Protect it with inert gases, such as argon or nitrogen, in vacuum graphite carbon tube furnaces to prevent burning. Only open the chamber when it has cooled to room temperature to avoid cracking.

4. Tungsten Chamber: Ultra-High Temperature Tolerance

Made of high-purity tungsten via powder metallurgy, this chamber offers the metal’s highest melting point, enabling long-term service at 2300℃. It is suitable for ultra-high-temperature sintering of tantalum, niobium, aerospace ceramics, and nuclear materials, ensuring full densification and preventing material reaction.

Note: Tungsten is brittle at room temperature—avoid collisions during the operation of vacuum tungsten sintering furnaces. Utilize gradient cooling post-sintering in these vacuum furnaces and avoid materials containing carbon or silicon. Regular surface inspections are required.

5. Heat-Resistant Steel Chamber: Practical for General Scenarios

Constructed from Cr25Ni20 steel, this chamber resists oxidation and creep, operating at a maximum temperature of 750℃ —a temperature that surpasses that of ordinary stainless steel. It is suitable for medium-temperature metal sintering, powder metallurgy enhancement, and ceramic debinding, making it ideal for industrial heat-resistant parts and automotive engine components.

Cost-effective and easy to maintain, it suits factory mass production and lab tests. Precautions: Avoid prolonged over-limit operation in vacuum heat-resistant steel thermal furnaces. Protect from low-melting metals, and cool slowly after shutdown. Inspect the chamber regularly for oxidation and cracks.

6. How to Choose the Right Chamber?

Focus on four core factors: process temperature, material characteristics, product requirements, and economy when selecting chambers for vacuum furnaces. Brother Furnace’s five-chamber options cater to a diverse range of industrial needs for these products.

For more information on high-quality vacuum furnaces, please do not hesitate to contact us. Brother Furnace is a professional manufacturer of vacuum electric furnaces, providing you with excellent service.