seo@bonaregroup.com

Email Us

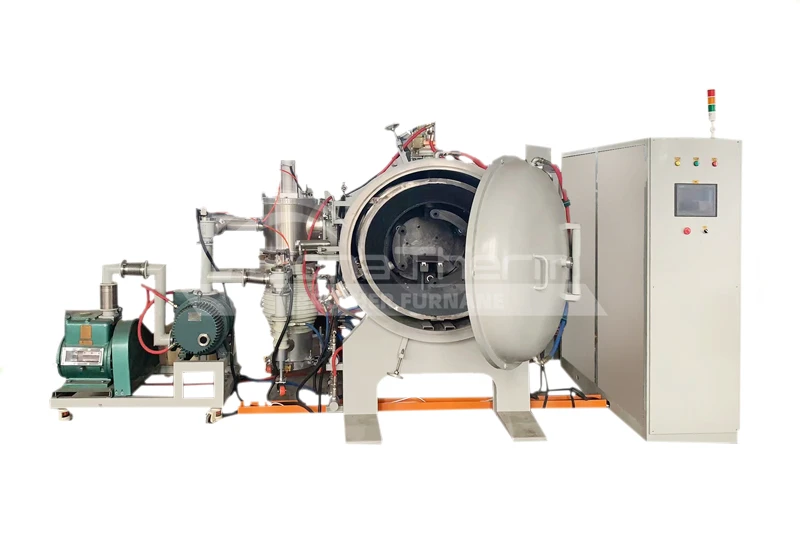

The vacuum graphite furnace is a high-performance, intelligent heating furnace developed by Brother's engineers and technicians after absorbing foreign temperature measurement and control technologies, intelligent technology, new materials technology, and furnace design technology. It is suitable for high-temperature treatment of materials under vacuum or gas protection.

Starting from the internal structure, we show you the unique design logic of vacuum graphite furnace products:

Using graphite as heating element.

Graphite soft felt and hard felt form a composite carbon fiber chamber.

Tungsten-rhenium thermocouple and infrared thermometer are used to measure temperature.

Tungsten-rhenium thermocouple can be automatically inserted and removed.

An observation window is provided on the chamber shell to facilitate observation of the heating conditions inside the chamber. The advanced front and rear door design makes it easy for customers to load and unload workpieces.

PLC automatic control system, the human-machine interface adopts high-definition touch screen, and has a built-in operating system developed by us.

Focusing on actual scene applications, we will highlight the advantages of vacuum graphite furnace equipment functions for you:

2400℃

1800℃ or 2200℃ optional

Upper limit alarm, deviation alarm, automatic stop at the end of program operation, no need for human supervision.

Vacuum graphite furnaces can cover multiple fields and demonstrate their cross-industry adaptability and practical value:

Aiming at the characteristics of various materials, the core advantage of the product is its compatible processing:

Focus on answering common questions to provide users with clear and practical usage guidelines:

A:Our vacuum graphite products utilize a strategically arranged graphite heating element, combined with a sophisticated temperature control system, to maintain a temperature differential within ±5°C. Furthermore, we utilize a carbon fiber composite furnace chamber insulation composed of imported soft and hard graphite felt to minimize heat loss and further ensure temperature uniformity.

A:Graphite is a material with high melting point and high temperature stability that allow chamber temperatures to easily exceed 2000°C, meeting the extreme high-temperature processing requirements of refractory metals and high-performance ceramics. Its structural stability at high temperatures also ensures high equipment reliability.

A:Graphite's excellent conductivity makes it a good conductor of heat, allowing for rapid heat transfer and rapid temperature ramping and cooling, significantly shortening process cycles and improving production efficiency while ensuring uniform temperature distribution within the chamber.

Present performance details with accurate data, intuitively showing the core technical specifications of the vacuum graphite furnace:

| Types | Heating Zone (Width x Height x Depth)mm |

Working Temperature(℃) | Power(KW) | Power Supply(V) |

|---|---|---|---|---|

| BR-18GVF-223 | 200X200X300 | 1800 | 60 | 380 |

| BR-18GVF-334 | 300X300X400 | 1800 | 100 | 380 |

| BR-18GVF-446 | 400X400X600 | 1800 | 160 | 380 |

| BR-18GVF-557 | 500X500X700 | 1800 | 220 | 380 |

| BR-18GVF-669 | 600X600X900 | 1800 | 300 | 380 |

| Types | Heating Zone (Width x Height x Depth)mm |

Working Temperature(℃) | Power(KW) | Power Supply(V) |

|---|---|---|---|---|

| BR-22GVF-223 | 200X200X300 | 2200 | 85 | 380 |

| BR-22GVF-334 | 300X300X400 | 2200 | 150 | 380 |

| BR-22GVF-446 | 400X400X600 | 2200 | 235 | 380 |

| BR-22GVF-557 | 500X500X700 | 2200 | 315 | 380 |

| BR-22GVF-669 | 600X600X900 | 2200 | 425 | 380 |

Control of all links from raw materials to finished products:

Stainless steel sheets and high-temperature-resistant alloys are selected, meeting vacuum sealing and load-bearing standards.

Cut raw materials according to design drawings using specialized equipment to ensure dimensional tolerances.

Bends and forms the sheet metal, processing the furnace shell and chamber components with a bending angle accuracy of ±1°.

Lathes are used to process precision components such as flanges and connectors, ensuring surface roughness control.

Weld the furnace body welds, ensuring airtightness on key components, and perform post-weld inspection.

Grinds and trims welded components to ensure a smooth appearance without sharp edges.

Electrostatically sprays the furnace shell and dries it.

Install the vacuum system, heating element, temperature control module, cooling system, and tighten connectors.

Conduct vacuum tests, temperature rise tests, and safety checks.

Internally cushioned with pearl cotton, externally covered with waterproof film and wooden crates, with anti-collision markings and equipment parameter labels.