seo@bonaregroup.com

Email Us

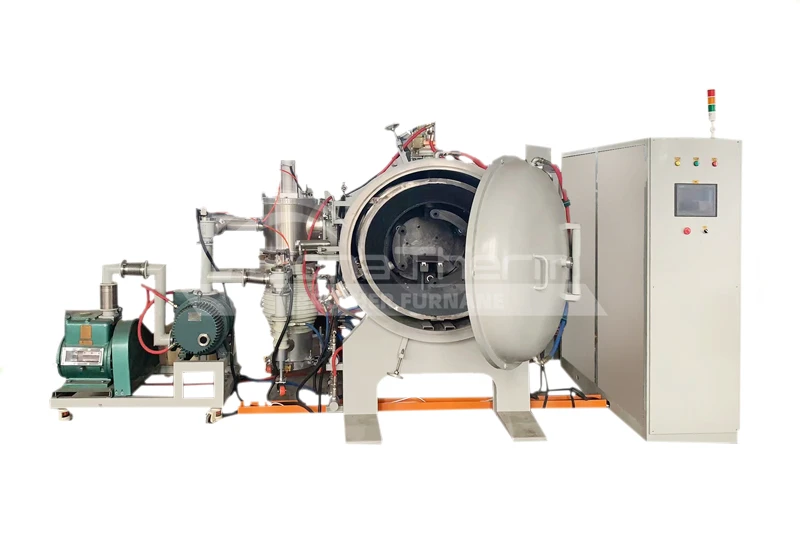

Brother Furnace's Vacuum Sintering Furnace provide you with precise temperature control and a clean, oxygen-free environment, ensuring high-quality results for advanced materials processing and research applications.

Vacuum sintering equipments are economical vacuum processing equipment. We offer a diverse and efficient product line to meet diverse applications and needs. The furnaces feature a compact design, easy operation, and excellent vacuum performance with uniform temperature distribution. They are suitable for high-temperature vacuum brazing and soldering of ceramics, metal composites, and alloys, and are widely used in a wide range of applications.

From vacuum sintering furnaces, vacuum atmosphere sintering furnaces, to graphite vacuum furnaces, our range includes models. Heating elements include resistance wire, silicon-molybdenum rods, and graphite rods. Temperature ranges include 750°C to 2300°C. These vacuum sintering services meet diverse needs in research and production.

Our vacuum sintering products are mainly used in the following fields

This is a key piece of equipment for powder metallurgy parts molding, primarily used to compact metal powders and then achieve particle bonding and densification through vacuum sintering.

This meets the precision sintering needs of high-end alloy components, particularly for processing high-temperature-resistant, high-strength materials.

This is a core piece of equipment for the tool and mold industry, used for sintering cemented carbide and superhard composite materials.

This focuses on the precision sintering of functional materials to ensure the performance stability of electronic components and new energy modules.

The following are the materials that can be processed and their classification

Metal Powders for Powder Metallurgy:Iron-based (such as carbon steel, alloy steel powder), copper-based (copper, copper alloy powder), stainless steel (304/316L powder).

Cemented carbide:tungsten carbide,cobalt (Co),titanium carbide (TiC),nickel alloys.

Superhard composite materials:diamond-metal matrix composites (such as diamond saw blade substrates).

Alumina (Al₂O₃), silicon nitride (Si₃N₄), silicon carbide (SiC) ceramics.

Aluminum-based silicon carbide (Al-SiC), titanium-based carbon fiber composites.

Choose chambers with different thermal field materials

1200°C/1700°C

Ceramic materials, ceramic composites, refractory metals

High cost performance and excellent vacuum effect High strength at high temperatures,no pollution

1350°C

High-temperature alloys (Nickel-based/Cobalt-based), Silicon Carbide (SiC) Ceramics, Silicon Nitride (Si₃N₄) Ceramics, High-purity metals (Tantalum, Niobium).

High strength at elevated temperatures, no pollution.

1800°C/2200°C

Tungsten Carbide (WC), Titanium Carbide (TiC), Graphene Composites, Carbon-Carbon (C/C) Composites.

Ultra-high temperature, cost-effective, thermal shock resistant.

750°C

Copper-based alloys, Aluminum alloys, Low-melting-point metal powders (Tin, Lead), Magnetic alloys (NdFeB).

Low temperature sintering has low power, low price, economical and practical.

2300°C

High purity ceramics, zirconium oxide

Ultra-high temperature, clean and pollution-free.