who we are?

BROTHER FURNACE

Leader in vacuum furnace manufacturer

Brother furnace specializes in the technological development of high-temperature vacuum electric furnaces and comprehensive solutions for vacuum heat treatment equipment. Leveraging the group's strong comprehensive strength, cutting-edge technology, and excellent service system, we have established the Brother furnace brand as a place of exceptional quality.

We promise that both our vacuum furnace products and services represent a guarantee of excellence and quality.

Brother Furnace

Vacuum Furnace Product Classification

Brother vacuum furnaces mainly include four types: Vacuum Sintering Furnace,Vacuum Brazing Furnace,Vacuum Heat Treatment Furnace and Vacuum Induction Melting Furnace. Our Vacuum Furnace products are widely used in high-end fields such as aerospace,scientific research institutes,experimental applications,mechanical manufacturing,etc.

Brother Furnace

Case Show

What our customer buys

Brother Furnace

Customer Reviews

What our customer says

Brother Furnace

Knowledge Explanation

The following are some explanations about Vacuum Furnace products to help you learn more.

-

- Brother Furnace

- Mar 05 2026

Maximizing Furnace Potential in Modern Material Processing

Our products are mainly divided into two categories: vacuum furnaces and experimental electric furnaces. They play a vital role in modern materials processing. In various industries and fields, they enable controlled heat treatment, and with their reliable heating performance, they lay the foundation for innovation in high-demand areas such as materials handling and industrial processing.

read more + -

- Brother Furnace

- Mar 04 2026

How Do Vacuum Brazing Furnaces Work?

A vacuum brazing furnace is a specialized high-temperature system used to bond metal parts through vacuum brazing. By processing materials inside a tightly controlled high-vacuum environment, it heats both the metal workpieces and the brazing filler metal until the filler melts, flows evenly into the joint gaps, and then solidifies to form strong, clean metallurgical bonds.

read more + -

- Brother Furnace

- Feb 11 2026

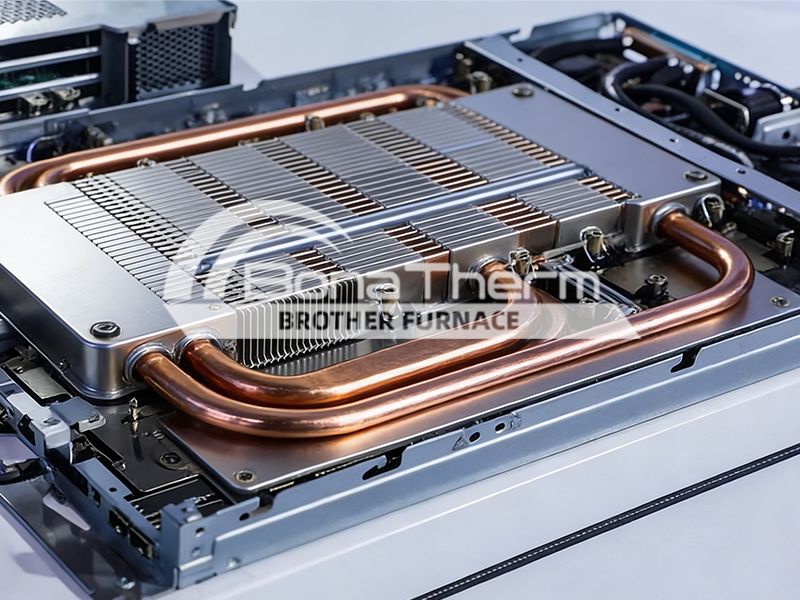

AI Liquid Cold Plate Pain Points: Solved by Vacuum Brazing Technology

As the "heat dissipation heart" of AI equipment, the welding precision and reliability of AI liquid cold plates directly affect the stable operation of computing power equipment. Vacuum brazing furnaces, as core brazing equipment, directly determine the quality of liquid cold plates, which is crucial for enterprises' competitiveness.

read more +