AI Liquid Cold Plate Pain Points: Solved by Vacuum Brazing Technology

- By: Brother Furnace

- 2026-02-11 00:54

With the rapid iteration of AI large models and large-scale deployment of high-density data centers, Liquid cooling has become the key to solving heat dissipation for computing power, driving the AI liquid-cooling plate industry into a high-quality development stage.

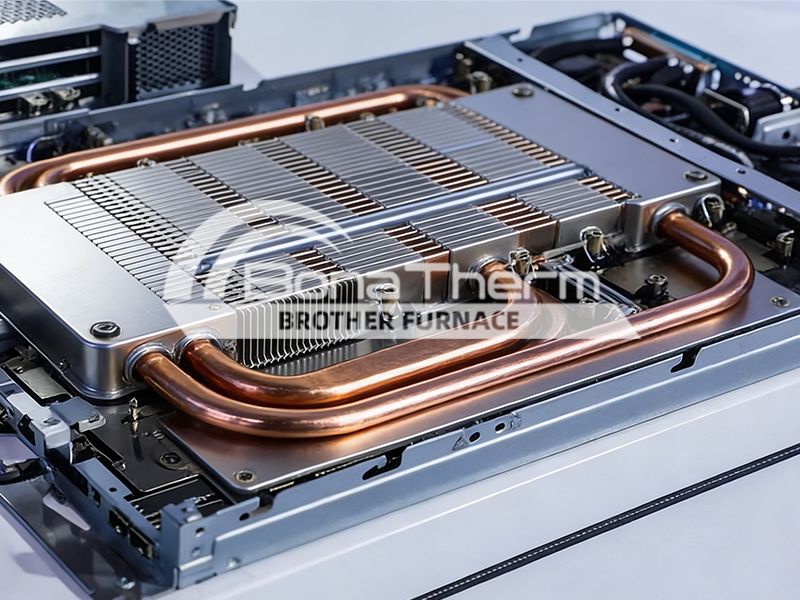

Liquid Cold Plates: The "Heat Dissipation Heart" of AI Equipment

As the "heat dissipation heart" of AI equipment, the welding precision and reliability of AI liquid cold plates directly affect the stable operation of computing power equipment.

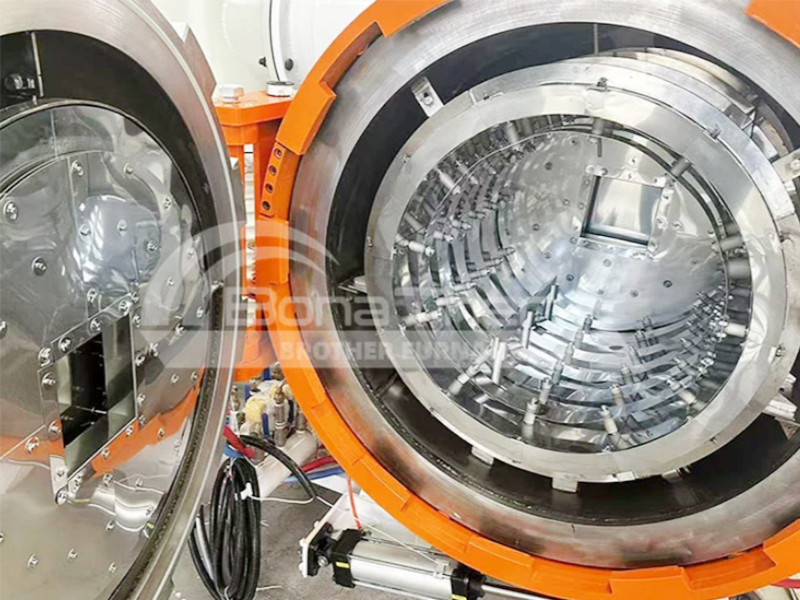

Vacuum brazing furnaces, as core brazing equipment, directly determine the quality of liquid cold plates, which is crucial for enterprises' competitiveness.

Growing Demand for AI Liquid Cold Plates Drives the Advancement of Vacuum Brazing Technology

The Operating Environment of AI Liquid Cold Plates Determines Their Quality Threshold

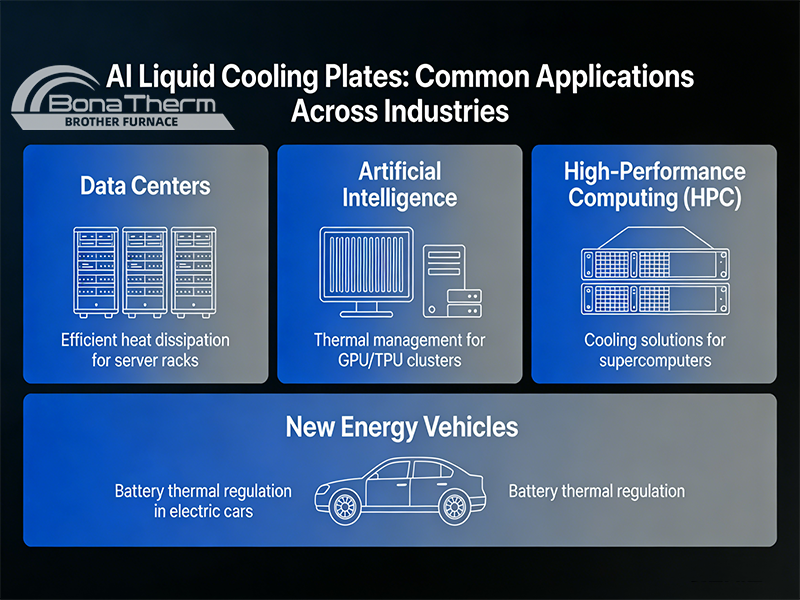

AI liquid cold plates are widely used in AI servers, semiconductor equipment, and data centers.

Operating in long-term high-temperature and high-pressure environments, they have higher requirements for overall quality, raising the threshold for vacuum brazing technology.

Stringent Requirements for Brazing in High-Demand Scenarios

The rising quality requirements for AI liquid cold plates impose higher standards on vacuum molybdenum brazing technology.

Traditional vacuum brazing furnaces and even some specialized equipment fail to meet the required precision and stability, becoming an obstacle to the upgrading of the AI liquid cold plate industry.

Industry Trend: Liquid Cooling Has Become Mainstream, and Brazing Technology Cannot Fall Behind

Cold Plate Liquid Cooling Dominates the Market, Driving the Iteration of Brazing Processes

Liquid cooling has become a must-have for enterprises, driven by AI computing power pressure, dual-carbon policies, and cost advantages.

Cold plate liquid cooling, as the mainstream, promotes the continuous upgrading of AI liquid cold plate brazing technology

Future Development Direction of AI Liquid Cold Plates and Brazing Technology

Future AI liquid cold plates will develop towards lightweight, high precision, and durability, requiring vacuum brazing technology to achieve controllable temperature, stable vacuum environment, and reduced welding defects to keep pace with the industry.

Customers' Actual Needs: How to Choose AI Liquid Cold Plate Brazing Equipment?

Key Indicators for Brazing Equipment Selection

For enterprises, choosing suitable liquid cold plate brazing equipment is critical.

The core requirement is that the equipment can meet the required temperature and vacuum degree to ensure a qualified brazing quality of AI liquid cold plates.

Practical Requirements for Equipment Performance and Cost

Enterprises also focus on precise temperature control, efficient cooling, and equipment stability to adapt to personalized production needs.

Cost performance is another key consideration, with AI data center brazing furnaces being popular choices.

Technological Breakthrough: Effectively Solving the Problems of Liquid Cold Plate Brazing

R&D Direction of High-Precision Vacuum Brazing Equipment

Focusing on industry needs and enterprise pain points, the R&D of high-precision vacuum brazing equipment has become a key breakthrough, aiming to solve the defects of traditional equipment in temperature control and vacuum stability.

Application Advantages of High-Precision Vacuum Brazing Equipment

High-precision vacuum equipment has been successfully applied, effectively solving AI liquid cold plate brazing problems.

It reduces welding defects, ensures efficiency and reliability, and supports mass production of high-quality AI liquid cold plates.

Vacuum Brazing: Boosting the AI Liquid Cold Plate Manufacturing Industry

Market Potential of Liquid Cold Plate Brazing Industry

With the booming liquid cooling industry, demand for AI liquid cold plates continues to grow, creating significant development opportunities for vacuum brazing technology and related equipment.

Opportunities and Challenges for Enterprises in the Liquid Cooling Track

Brother Furnace has always kept pace with the times and has made new technological breakthroughs in the field of high-precision brazing and liquid cooling manufacturing.

We look forward to providing more companies in the artificial intelligence, big data, and 3C electronics industries with high-performance vacuum brazing equipment and technical solutions!