What role does medium-frequency induction heating play in high-efficiency industrial heat treatment?

- By: Brother Furnace

- 2026-01-15 21:24

Industrial upgrading has driven the evolution of thermal processing technologies, with medium-frequency induction heating (MFIH) standing out as a core solution.

With its advantages of rapid heating, uniform temperature distribution, and high energy efficiency, MFIH has largely replaced traditional flame furnaces and resistance furnaces.

Meanwhile, the vacuum induction melting furnace perfectly complements MFIH, forming a synergistic processing solution that meets the demands of high-end precision machining and heat treatment.

1. Technical Core: Principles and Equipment Composition of MFIH

1.1 Working Principles and Frequency Characteristics

Medium-frequency induction heating operates in a frequency range of 1000–10000 Hz, falling between the power frequency and high frequency ranges.

This frequency band strikes an optimal balance between heating depth and efficiency, making it ideal for most metal thermal processing applications, especially induction heat treatment of workpieces.

Its core principle hinges on electromagnetic induction and Joule heating, which generate heat directly within metal workpieces, eliminating heat loss associated with external heat sources.

1.2 Core Working Process of the vacuum induction furnace

The MFIH process comprises three key stages:

First, a medium-frequency power supply converts ordinary alternating current into medium-frequency current.

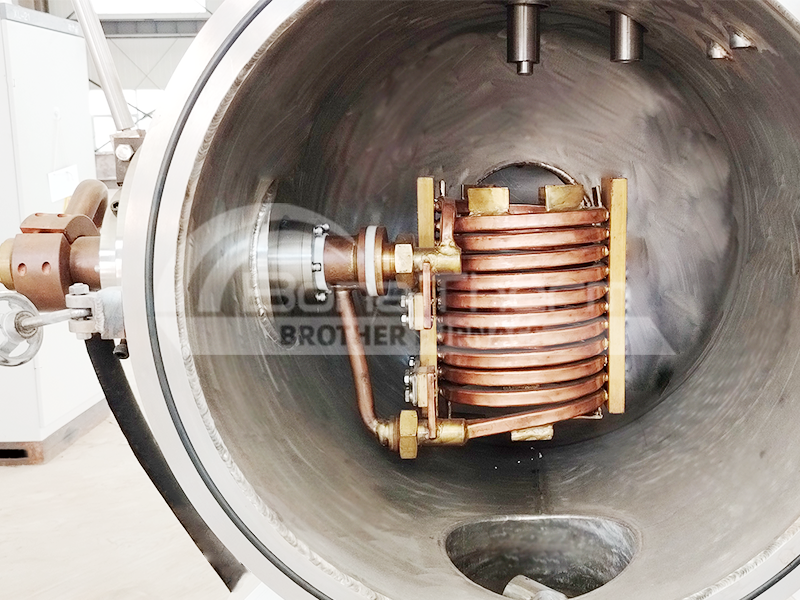

Second, this current flows through a spiral induction coil, creating an alternating magnetic field.

Third, placing a metal workpiece in this magnetic field induces eddy currents, which rapidly heat the workpiece—this is the core working mechanism of MFIH.

1.3 Main Equipment Components

MFIH systems comprise five core components: a medium-frequency power supply responsible for energy conversion and frequency regulation, a customized induction coil equipped with a cooling system, a control system that enables precise parameter adjustment and automation, a magnetic yoke designed to minimize energy loss, and a compensation capacitor that enhances energy efficiency.

2. Core Advantages: Complementary Value with Vacuum Induction Melting Furnaces

2.1 Core Advantages of MFIH

MFIH outperforms traditional heating technologies in terms of efficiency, precision, and environmental friendliness.

By generating heat directly inside workpieces, MFIH minimizes heat loss, achieving higher thermal efficiency and rapid heating—single workpieces can be heated in just a few minutes.

For pre-forging metal heating, MFIH controls steel billet loss to below 1%, lower than flame furnaces, thereby reducing material waste and boosting production efficiency.

Adjustable frequency and power allow for precise control of heating range, depth, and temperature, supporting both overall and localized heating. This not only reduces workpiece deformation but also extends mold service life.

2.2 Complementary Value with Vacuum Induction Melting Furnaces

While MFIH is limited to conductive metals and focuses on efficient heating and forming, vacuum induction melting furnaces fill the gap in high-end material processing.

The vacuum environment isolates air and impurities, preventing metal oxidation and contamination—a critical feature for producing high-purity alloys and special materials used in aerospace, semiconductors, and precision instrumentation.

Vacuum induction melting furnaces lay a solid foundation for material purity, while MFIH enables efficient, precise thermal processing, ensuring final products meet strict performance standards.

This combination of MFIH and vacuum induction melting furnaces also caters to diverse production needs, from small-batch high-end material smelting to large-scale industrial part heating.

3. Application Implementation: Industrial Applications of MFIH and Vacuum Melting

3.1 Application in Metal Smelting

Medium-frequency induction melting furnaces are dominant in small-to-medium batch, multi-variety metal smelting. Electromagnetic induction stirring ensures uniform metal composition, thereby improving casting quality.

Vacuum induction melting furnaces are the preferred choice for high-end materials. The vacuum environment isolates air and impurities, guaranteeing high material purity for demanding fields such as aerospace and semiconductors.

3.2 Other Industrial Application Scenarios

MFIH is also widely used in pre-forging heating, auto part forming, pipe processing, and metal heat treatment.

In mechanical manufacturing, it ensures workpiece plasticity; in auto parts production, it reduces internal stress; and in pipe processing, it prevents wall thinning or cracking—all of which contribute to stable product quality.

As a core supporting technology, MFIH plays an irreplaceable role in enhancing workpiece performance across various industries.

4. Future Trends: Technology Integration Empowers High-End Manufacturing

Driven by the demands of industrial automation and energy conservation, MFIH is moving toward higher efficiency, intelligence, and integration.

In the future, closer collaboration between MFIH and vacuum melting furnaces will lead to integrated, intelligent solutions, further improving manufacturing efficiency, product quality, and the competitiveness of industrial enterprises.

- Pre: BR-QCL Vacuum Furnace: Precision Heat Treatment, Empowering Industry

- Next: Sorry!