Vacuum Furnace Heating Methods: A Practical Guide to Resistive and Inductive Heating

- By: Brother Furnace

- 2025-11-24 18:41

In material and precision processing, vacuum furnaces are indispensable for ceramic sintering, metal purification, and aerospace component processing, thanks to their oxidation-free and pollution-free advantages.

As the core of vacuum furnaces, the heating system directly determines temperature control accuracy, process adaptability, and energy efficiency. Resistive heating and inductive heating are the two mainstream technologies in the industry.

As a professional vacuum furnace R&D enterprise, Brother Furnace has integrated both into its product portfolio to address diverse industrial needs.

1. Resistive Heating: A Widely Used Basic Heating Method

1.1 Energy Conversion Principle Based on Joule's Law

Resistive heating is the most commonly used heating technology in vacuum furnaces, and its principle is based on Joule’s Law:

When an electric current passes through the resistance of a conductor, heat energy is generated, which is then transferred to the workpiece in the form of radiation.

According to different temperature requirements and process characteristics, Brother Furnace equips its vacuum furnaces with various types of resistive heating elements.

1.2 Full-Temperature Range Component Selection and Corresponding Application Scenarios

For medium- and low-temperature applications, our standard vacuum heat treatment furnaces utilize flexible, cost-effective resistance wires. Their multi-zone configuration ensures uniform furnace temperature, ideal for metal annealing and aging.

Medium and high-temperature vacuum sintering furnaces adopt high-temperature-resistant silicon carbide or molybdenum disilicide rods. These semiconductor elements enable precise temperature control, making them ideal for sintering alumina and silicon nitride ceramics.

High-temperature purification graphite furnaces use graphite rods or high-purity molybdenum strips. Their excellent thermal stability and low volatility protect sensitive materials, such as titanium alloys and optical glass, in harsh vacuum environments.

1.3 Three Core Advantages for Multi-Scenario Adaptation

Resistive heating is widely used in Brother Furnace’s products, with its core advantages reflected in three aspects:

First, high temperature control accuracy. The temperature difference inside the furnace can be controlled within ±5℃ through the PID temperature control system, meeting the processing requirements of precision parts.

Second, a wide adaptation range. From small laboratory furnaces to large industrial furnaces, efficient heating can be achieved through the combination of components.

Third, convenient maintenance. The replacement cost of resistive elements is low, and only regular inspection of terminal blocks is necessary during daily use to ensure the stable operation of the equipment.

2. Inductive Heating: An Efficient Heating Solution for Special Processes

2.1 Efficient Heating Principle of Eddy Current Heating

Induction heating is a heating technology developed by Brother Furnace for special processes.

Its principle is that alternating current generates an electromagnetic field, which induces eddy currents inside the workpiece, and these eddy currents generate heat, thereby causing the workpiece to rise in temperature.

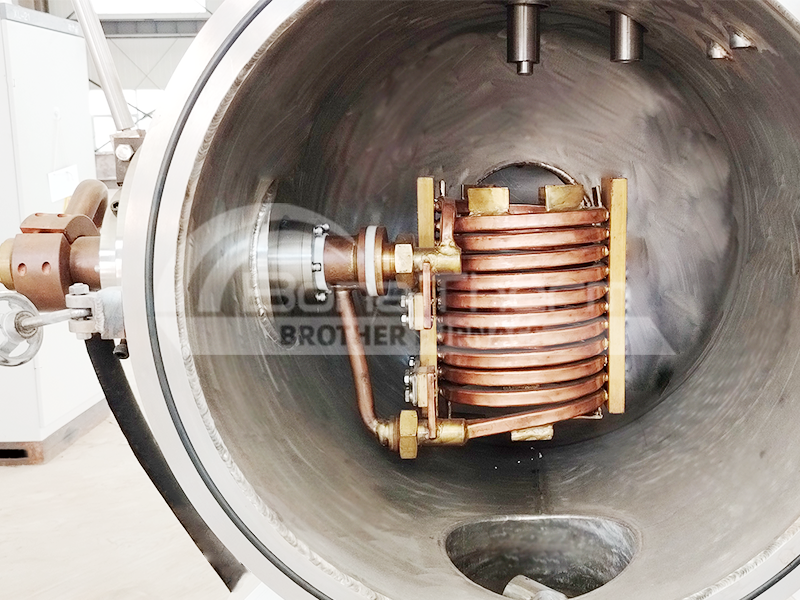

Our induction heating vacuum melting furnaces are equipped with IGBT intermediate-frequency power supplies, featuring induction coils wound with copper tubes as the core components.

The maximum heating temperature can reach 2300℃, which is mainly suitable for processes such as metal melting and brazing.

2.2 Typical Application Scenarios and Unique Technical Features

In precious metal melting, the advantages of intermediate frequency inductive vacuum melting furnaces are particularly prominent: eddy current heating does not require direct contact with the workpiece, which can avoid component contamination and ensure the purity of precious metals such as gold, silver, and platinum.

The heating speed is more than 30% faster than that of vacuum sintering furnaces, and the melting and casting of small-batch metals can be completed within 10 minutes, effectively improving production efficiency.

In the brazing process of aerospace titanium alloy components, the local heating characteristic of inductive heating allows for the accurate control of the welding area's temperature, thereby avoiding the impact of overall temperature rise on the original mechanical properties of the components.

This feature is difficult to replace with resistive heating. However, there is no absolute superiority or inferiority between resistance heating and induction heating. They are adapted to different process requirements.

3. Selection Guide: Meeting Requirements is the Core Principle

With the characteristics of “stability, versatility, and low cost”, resistive heating is the first choice for general application scenarios, covering more than 70% of Brother Furnace's vacuum furnace product lines.

For mass production scenarios, such as ceramic sintering and conventional metal heat treatment, resistive heating vacuum furnaces are preferred due to their better cost-effectiveness.

Induction heating, with the advantages of “high efficiency, cleanliness, and local heating”, focuses on the high-end special process field.

When it comes to needs such as melting precious metals and precision brazing, inductive heating models can better meet the technical requirements.

4. Core Tenet: Providing Suitable Solutions Focused on Customer

The iteration of vacuum furnace heating solutions has consistently prioritized “precise temperature control and process adaptation” as its core goal, aiming to meet the actual production needs of customers.

Through the mature application and optimization of these two heating methods, Brother Furnace offers a range of vacuum furnace solutions tailored to customers across various industries, ensuring that production needs in diverse scenarios are accurately met. This is also the core value of us.