Solution to the oil return problem of vacuum diffusion pump in vacuum brazing furnace

- By: Brother Furnace

- 2025-10-16 01:20

Will the diffusion pump return oil if the oil temperature is not high enough?

Insufficient oil temperature in the diffusion pump will not only cause oil backstreaming, but it is also one of the main causes of severe oil backstreaming.

Diffusion pumps are mainly used in vacuum brazing furnaces.

Diffusion pump is the core equipment for vacuum furnaces to achieve high vacuum processes, and is often used with rotary vane vacuum pump, mechanical pump, and other backing pumps.

The vacuum unit of the vacuum brazing furnace is composed of a mechanical pump + a diffusion pump, and the vacuum cutting-tool brazing furnace is a direct-connected pump + a diffusion pump.

Their performance directly determines the vacuum level, process stability, and product quality of the vacuum furnace.

They are widely used in precision vacuum processes in metal processing, electronics, semiconductors, optics, and other fields.

It is necessary to understand the working principle of the diffusion pump:

1. An electric heater at the pump base heats the pump oil, generating a large amount of oil vapor.

2. The oil vapor is ejected upward along the draft tube, forming a supersonic vapor jet.

3. These high-speed jets of oil vapor collide with and carry gas molecules from the pumped container, compressing them downward.

4. After being cooled by the water-cooled pump walls, the oil vapor condenses back into liquid and flows back to the pump base for recycling.

5. The backing pump then extracts the compressed gas molecules.

Insufficient oil temperature can cause oil back streaming through two main mechanisms:

Oil backstreaming occurs when pump oil vapor flows in the opposite direction and enters the vessel where a high vacuum is required.

1. Collapse or failure of the oil vapor jet:

Diffusion pumps require the pump oil to be heated to a specific temperature to form a high-speed oil-vapor jet. If the oil temperature is insufficient, the pump oil cannot fully vaporize, and the vapor flow rate and pressure will not meet the design standards, causing the oil-vapor nozzle jet to collapse or fail.

This disrupts the vacuum gradient in the pumping channel, causing the formed oil vapor to lose its directional jet momentum and flow back into the vacuum container.

2. A surge in the backing pressure of the vacuum pump:

Insufficient oil temperature reduces the diffusion pump's pumping efficiency, preventing the timely removal of gas from the vacuum system, leading to a sudden increase in system backing pressure.

When backing pressure exceeds the normal operating threshold of the diffusion pump, the oil vapor ejection resistance increases, disrupting the originally directional pumping cycle. Due to the pressure differential, the oil vapor flows backward into the high vacuum vessel, causing oil backflow.

The following are the steps to be followed when operating a diffusion pump:

1. Sufficient preheating:

After starting the diffusion pump heater, you must wait for a long enough time to ensure that the pump oil fully reaches the operating temperature. Usually 30-45 minutes, please refer to the pump manual for the specific time. Never open the high vacuum valve during the preheating period.

2. Shutdown in the correct order:

When shutting down, first close the high vacuum valve to isolate the vacuum chamber. Then stop heating, but continue running the pump, cooling water, and backing pump until the pump oil has cooled to room temperature.

This step is to prevent residual hot oil vapor in the pump from flowing back into the vacuum chamber during the cooling process.

3. Use Chevron Baffle and Cold Trap:

Installing a baffle or trap between the diffusion pump and the vacuum chamber can effectively condense the oil vapor that may flow back, which is the last line of defense to protect the vacuum chamber.

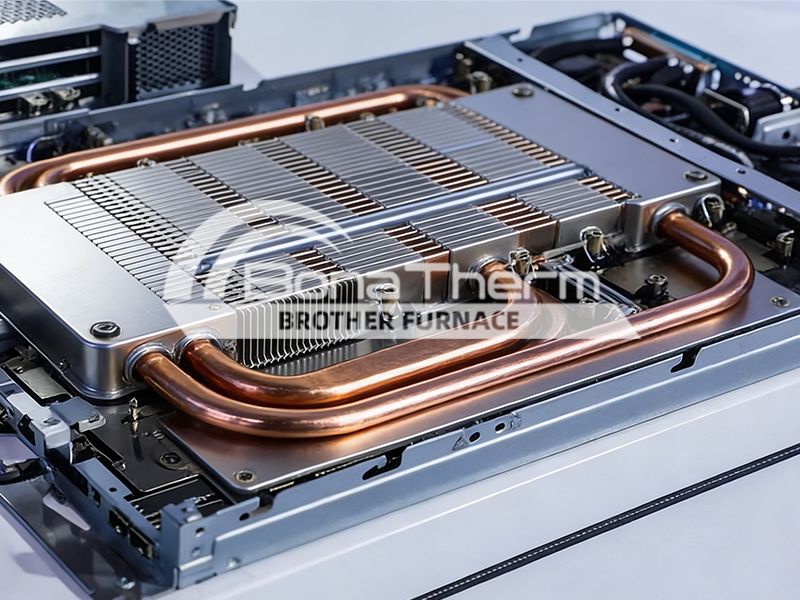

Vacuum brazing furnace and vacuum cutting-tool brazing furnace are the core equipment for achieving high vacuum, high temperature, high precision, pollution-free, and oxidation-free brazing. It is equipped with a controllable low-pressure and insulation system and can braze metals, ceramics, and other materials. It is very suitable for applications with high standards and high requirements.

Mastering the targeted solutions to these oil return problems and using vacuum pumps in a standardized manner can effectively improve the operating efficiency of the equipment, reduce the risk of failure, and provide a solid guarantee for the stable operation of the vacuum furnace.