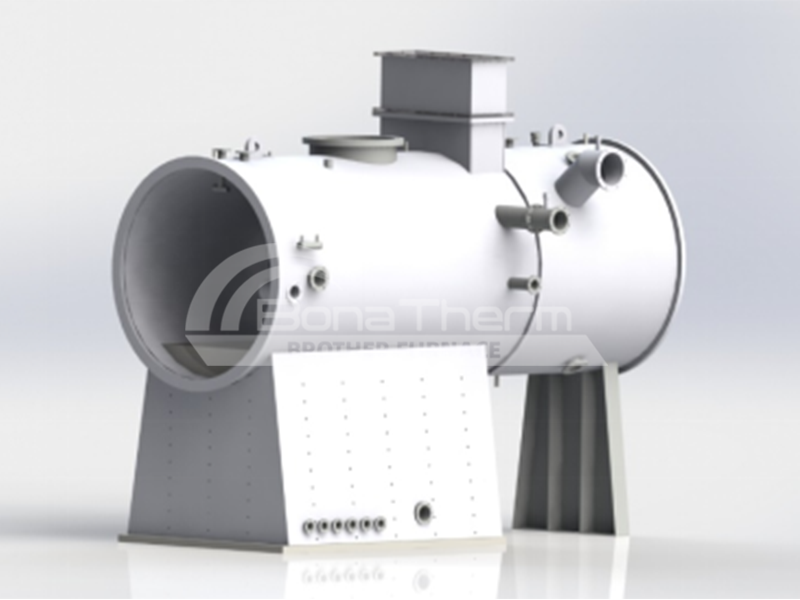

BR-7QHSYCL Series: Vacuum Oil Quenching Furnace for Precision Heat Treatment

- By: Brother Furnace

- 2025-12-18 00:21

In high-end manufacturing, the precision of material heat treatment directly shapes product performance.

Our self-developed BR-7QHSYCL Series Vacuum Double-Chamber Oil Quenching Furnace combines multiple proprietary technologies.

With fully automated control and stable processing, it’s become essential for manufacturing key components like high-speed steel and precision bearings—offering reliable support for boosting material performance.

1. Core Advantage: Precise and Controllable Thermotechnical Performance

Intuitive Control & High Temperature Precision

The core advantage of this oil quenching furnace lies in its precise and controllable thermotechnical performance. Equipped with a 15-inch touch screen and a fully automatic control system, the equipment features intuitive and convenient operation.

Combined with a British Eurotherm industrial PID signal controller, it achieves a temperature control accuracy of ≤±1℃, laying a solid foundation for process stability.

Flexible Temperature Adjustment

Its maximum design temperature can reach 1320℃, and the heating rate is adjustable within a range of 0-20℃/min, which meets the heat treatment requirements of various materials.

Uniform Temperature Field Distribution

In terms of temperature field uniformity, the equipment performs excellently—the uniformity index of ±5℃ ensures that the parts in the furnace are heated uniformly, effectively avoiding performance deviations caused by temperature differences.

2. Technical Highlight: Efficient and Environmentally Friendly Vacuum System

Superior Vacuum Performance

The optimized design of the vacuum system is another major highlight of this equipment. The cold-state ultimate vacuum degree of the heating chamber can reach 6×10⁻¹Pa, and a stable vacuum environment can be maintained after full furnace baking.

After being heated, insulated, and cooled in this environment, the parts have a bright surface without oxide color, completely solving the problems of carburization and element depletion in traditional heat treatment.

Efficient Vacuum Pumping & Environmental Protection

The vacuum pumping speed is also efficient—it only takes 15 minutes to pump from atmospheric pressure to 5Pa. Cooperated with the pressure rise rate of ≤0.67Pa/h, it greatly improves production efficiency.

The oil fume purification device at the outlet of the mechanical pump further realizes environmentally friendly emission, meeting the green production requirements of modern factories.

3. Structural Design: Dual Guarantee of Practicality and Safety

Scientific Double-Chamber Structure

The structural design of the equipment takes both practicality and safety into account. It adopts a horizontal double-chamber structure, with the front chamber as the cooling chamber and the rear chamber as the heating chamber.

They are separated by a vacuum-sealed heat-insulating gate valve. The double-wall water-cooling design effectively protects the sealing elements and prolongs the service life of the equipment.

Efficient Heating Chamber Configuration

Inside the heating chamber, the graphite soft felt insulation layer and the graphite heating elements are evenly arranged to form an efficient thermal field.

Stable Mechanical Transmission System

The suspended support rod fixing design ensures that the heating tube does not deform and is easy to replace. The mechanical system integrates a lifting mechanism and a horizontal feeding mechanism, cooperating with the oil stirring and oil temperature control system to realize stable transmission and uniform cooling of parts.

4. Wide Adaptability: Customizable Options for Multiple Industries

Diversified Process & Material Adaptability

This equipment is widely popular across various industries thanks to its strong adaptability.

It excels at basic processes like vacuum oil quenching and vacuum gas quenching.

Moreover, it meets the aging and annealing requirements of diverse materials, including high-speed steel, high-alloy tool and die steel, and carburized steel.

This makes it suitable for processing a range of products, such as precision bearings and oil pump nozzle components.

Customizable Models for Different Needs

For different production scenarios, the effective heating area size and loading capacity of the equipment can be customized on demand. There are multiple models, with loading capacity ranging from 100kg to 500kg, providing flexible choices for enterprises of different scales.

Market Recognition: A Powerful Assistant for High-End Manufacturing

With its professional performance, the BR-7QHSYCL Series Vacuum Oil Quenching Furnace has provided customized solutions for numerous enterprises and won widespread market recognition—whether in the high-precision aerospace sector or the stability-focused automotive manufacturing industry.

If you are in the heat treatment industry, please feel free to contact us to learn more about our equipment. We can provide you with professional technical support and services.